In today’s rapidly evolving landscape, characterised by large populations and dynamic business activities, the demand for efficient water treatment systems has surged to large levels. With the exponential increase in the sewage volume, the pressure intensifies on treatment facilities to ensure not only safe discharge but also operational efficiency and cost competitiveness.

However, navigating the complexities of investing in water treatment facilities amidst such demands can pose a sensible challenge for the industry.

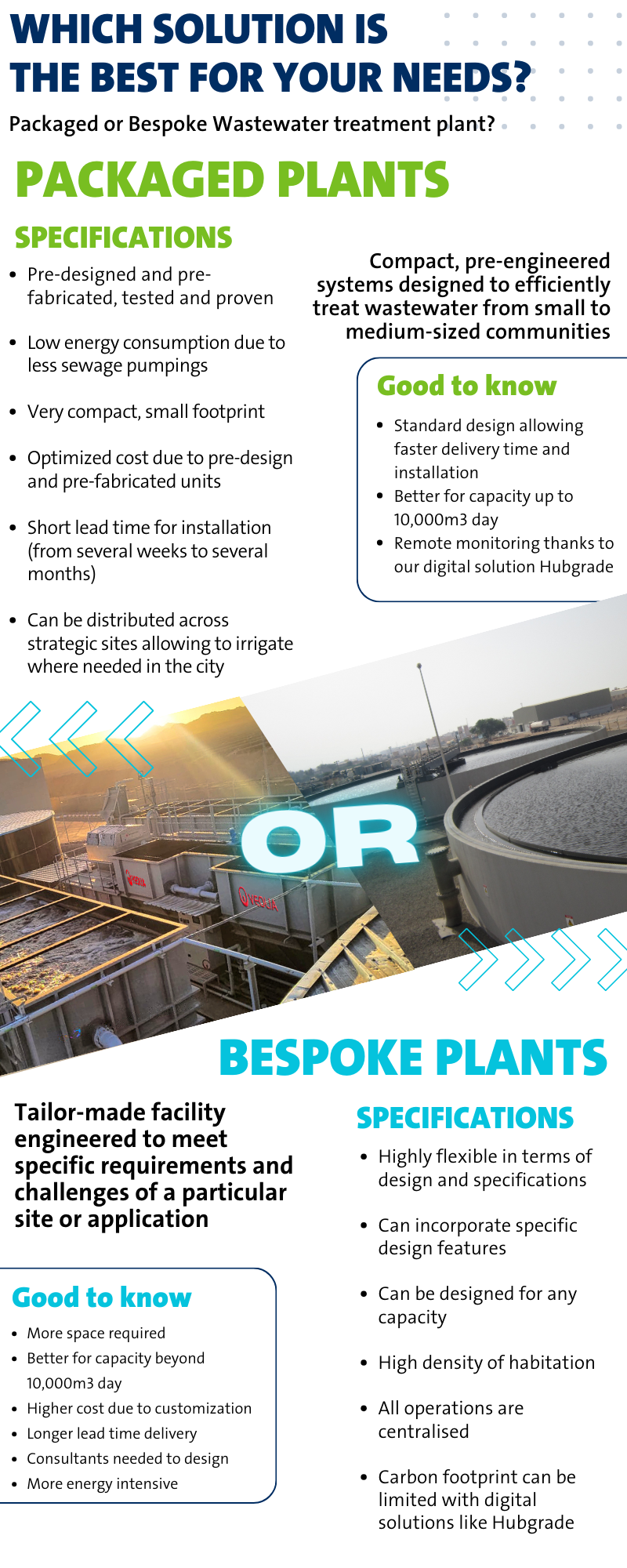

Enter the debate between packaged and bespoke wastewater treatment plants, both offering solutions to manage water treatment processes but with distinct characteristics customised to different needs. Understanding these differences is crucial in determining which option aligns best with your requirements. Let’s delve deeper into the details of the structure of each to unravel the benefits and points to consider during the decision making process, that will help you to find an optimal solution for your water treatment endeavours.

Interested?

Benefits of Packaged Wastewater Treatment Plants:

Packaged wastewater treatment plants excel in handling capacities below 10,000 m3/day, making them ideal for small and moderate-scale operations. Their modular design allows for easy scalability within this range, offering flexibility as your needs evolve.

One of the key advantages of packaged plants lies in their ability to be deployed across various locations, facilitating decentralised treatment. This results in reduced pumping requirements and network infrastructure for both sewage and TSE, translating to significant cost savings and operational efficiency. Moreover, their standardised nature ensures swift installation, minimal maintenance, and decentralised & mobile operations, guaranteeing hassle-free management of the industrial wastewater.

From an environmental perspective, packaged plants boast a low carbon footprint owing to their efficient design, which minimises energy consumption, particularly in sewage pumping. Additionally, advancements such as digital solutions can also help you to optimise your operations. As an example, Veolia Water Technologies Middle East is providing clients with a Hubgrade digital solution in the full value offered with the packaged plant with real-time monitoring and performance optimization to further mitigate carbon emissions.

Veolia offers two options for packaged plant solutions to their clients: the modular and plug-and-play MBBR Pack units, available with capacities of 500 or 1000 m³/day, and the Ecodisk Pack, designed for smaller capacities up to 100 m³/day, ideal for domestic wastewater treatment in settings such as hotels, construction sites, and accommodation areas, while meeting water reuse quality standards.

For permanent installations lasting around ten years, packaged plants offer a convenient and reliable solution, providing peace of mind through proven and pre-designed systems.

Points to consider

While packaged plants offer cost-effective solutions for smaller capacities, it can face limitations in handling capacities beyond 10,000 m3/d, making them unsuitable for large-scale applications.

Moreover, their standardised nature may not always align with specific client requirements, necessitating compromises in functionality or performance. When standardised solutions encounter unique client needs, adjustments are often required, potentially resulting in trade-offs between meeting client demands and maintaining standardised processes.

Benefits of bespoke wastewater treatment plants

In contrast, bespoke plants shine in handling capacities exceeding 10,000 m3/d, catering to larger-scale operations with precision and efficiency. Their customizable design allows for tailoring to specific client requirements, ensuring optimal performance and seamless integration with existing infrastructure.

Flexibility is a hallmark of bespoke plants, offering adaptability to unique project needs and environmental constraints. Whether it's optimising layout or incorporating specialised features, bespoke solutions can deliver unique customised solutions for specific clients requirements, while the incorporation of biogas technology presents opportunities for energy optimization.

In addition, with the help of digital solutions, such as Hubgrade Performance Plant solution, the carbon footprint levels can be reduced. The plant module is an online digital twin designed to enhance wastewater treatment plant operations. Utilizing real-time data and advanced algorithms, it continuously provides optimized setpoints to the PLC control and delivers valuable insights to your team.

This scalability extends to different design modifications made by the customer, ensuring alignment with evolving regulatory standards and client preferences.

Points to consider

However, despite their scalability and customization capabilities, bespoke plants come with a higher price tag, particularly for smaller capacity installations. This cost premium reflects the bespoke nature of these solutions and the added complexity involved in design and implementation of the system.

Furthermore, bespoke plants may require more extensive planning and design phases, definitively leading to longer lead times compared to packaged alternatives. Due to the nature of bespoke wastewater treatment plants, its design specifications may also pose challenges in terms of meeting timing to follow all regulatory standards or specific client preferences.

Location

One critical factor to consider is the geographical location of your water treatment facility. Depending on the geographical and environmental conditions, one type of plant may offer distinct advantages over the other. For instance, in remote or challenging locations where access to infrastructure is limited, packaged plants with their modular design and ease of installation may prove to be a more applicable solution. Conversely, in densely populated urban areas where space constraints and regulatory requirements are strict, bespoke plants with their customizable designs may offer a better option for the client.

Digitalization

Another aspect to consider is the technological advancements and innovations driving the water treatment industry forward. As digitalization and automation become increasingly popular, both packaged and bespoke plants can leverage these technologies to enhance efficiency, reduce operational costs, and minimise environmental impact. Integrating smart sensors, predictive analytics, and remote monitoring capabilities can optimise performance and ensure compliance with regulatory standards.

Sustainability

Furthermore, the role of sustainability in water treatment cannot be overstated. Beyond minimising energy consumption and carbon emissions, both packaged and bespoke plants can explore alternative energy sources such as solar, wind, or hydropower to further reduce their environmental footprint. Additionally, incorporating circular economy principles such as resource recovery and reuse can maximise resource efficiency and minimise waste generation.

Making a decision

Thus, while the decision between packaged and bespoke wastewater treatment plants may seem daunting, a thorough evaluation of your specific requirements, coupled with an understanding of the possible benefits and other points to of each option, will empower you to make an informed choice that aligns with your objectives and maximises the value of your water treatment investment.

With careful consideration, strategic planning, and insightful discussions with industry experts you can succeed in your wastewater treatment journey that not only meets your immediate needs but also lays the foundation for sustainable and resilient water management practices in the years to come

Expanding the Discussion: How to make the right decision?

While the mentioned points provide a comprehensive overview of the comparison between packaged and bespoke wastewater treatment plants, it’s essential to delve deeper into certain aspects to further clarify the decision-making process for your organisation.

Essential criteria for optimal choices

In the debate between packaged and bespoke wastewater treatment plants, there is no one-size-fits-all solution. The optimal choice hinges on factors such as capacity requirements, budget and time and time constraints, and project specifications.

For moderate-scale operations with predictable capacity needs, packaged plants offer a cost-effective and efficient solution, ideal for decentralised deployments and temporary installations. On the other hand, bespoke plants cater to larger-scale projects demanding customization, scalability, and precision performance.

Ultimately, the key lies in conducting a comprehensive assessment of your requirements and evaluating the pros and cons of each option to make an informed decision that optimises both performance and cost-effectiveness in your water treatment endeavours.